What is the Most suitable Packaging material for E-commerce and Logistics?

Air cushion film, also known as bubble wrap, is typically made primarily of high-density polyethylene (HDPE). Two layers of film are heat-pressed together at approximately 180 degrees Celsius, and then inflated using a heat-sealing inflator during the packaging process. It is lightweight, occupies little space before packaging, has good transparency, and is non-toxic and odorless. By adding different additives to the plastic raw material, various special-purpose air cushion films can be produced, such as anti-static air cushion films for packaging electronic components and other special products. These prevent static electricity and provide cushioning and shock absorption.

Besides air cushion film, what other packaging materials are commonly used in E-commerce Logistics packaging?

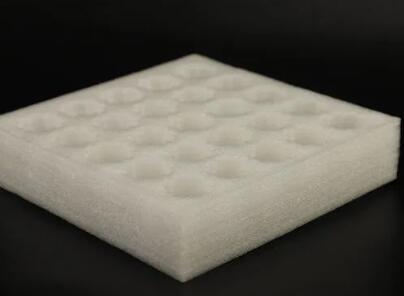

Other traditional cushioning materials include: sprayed plastic foam, pearl cotton, raffia, newspaper, etc.

Why do E-commerce companies prefer Bubble wrap?

First, e-commerce companies and manufacturers need to consider the space occupied by cushioning materials and storage requirements. Second, how can they utilize limited floor space to store more valuable items, reduce unnecessary space occupation, and increase the storage capacity of goods? Bubble wrap can solve these problems.

Bubble wrap contains moderately sized air bubbles that absorb impacts from all directions, providing excellent cushioning protection for products. Composed of 95% air and 5% composite materials, bubble wrap is completely flat before inflation, compact in size, and space-saving, significantly reducing transportation, storage, and usage costs.

Compared to Plastic Foam and Pearl Cotton:

Compared to other cushioning materials (such as plastic foam and pearl cotton, which occupy a lot of storage space), bubble wrap is produced in roll form, taking up minimal space. It only needs to be inflated for use. The space-saving characteristics of bubble wrap can save businesses more storage space. Therefore, businesses with limited storage space need not worry. Bubble wrap can save you a significant amount of storage space.

Compared to Newspaper and Foam Materials:

As a new type of logistics and express packaging cushioning material, the shock-absorbing effect of bubble wrap is self-evident. Whether it’s traditional newspaper or new foam materials, their cushioning performance is far inferior to that of bubble wrap. The main reason is the insufficient cushioning performance of these materials. As an air-cushioned packaging material, bubble wrap can withstand pressure exceeding 85 kg without breaking.

What are the Key Features of Air cushion film?

- Ready to Use, Highly Efficient and Convenient. Bubble wrap can be inflated online in real time, used while inflating. It doesn’t take up much space, saving significant storage and transportation costs. One roll of AIRSISTEM bubble wrap is equivalent to 90 times the space required for foam packaging.

- Higher Nylon Content, Better Flexibility. Bubble wrap has a nylon content of up to 23.6%. Higher nylon content results in better puncture resistance and extensibility. This flexible, puncture-resistant cushioning bladder can withstand multiple impacts and can be produced under high pressure. Spherical deformation evenly absorbs impact energy, allowing it to maintain its protective function even after multiple impacts.

- Significant Economic Benefits. Compared to traditional cushioning materials, bubble wrap offers significant advantages such as lower packaging material costs, lower storage costs, and lower waste disposal costs.

- Professional Backflow Check Valve, 80% Improved Airtightness. Each individual air chamber of the bubble wrap has a backflow check function, ensuring that even if a single bubble ruptures, the overall protective effect remains unaffected. Six consecutive months of airtightness testing have proven that bubble wrap has excellent moisture-proof and waterproof performance, with an air loss rate of only 7%.

- Easy to tear with pre-cut perforations. The bubble wrap is embossed with perforations for easy tearing. You can choose different numbers of airbags according to the product size and tear off any number of airbags as needed, avoiding material waste.

Conclusion:

Cushioning film represents a significant advancement in e-commerce packaging, perfectly blending protection, efficiency, and sustainability. Its lightweight construction reduces transportation costs, while its superior shock absorption minimizes product damage during transit. Compared to traditional materials like bubble wrap or foam, cushioning film is more space-efficient, easier to store and handle, thus simplifying logistics operations.

каталог seo агентств [url=https://www.reiting-seo-kompaniy.ru]https://www.reiting-seo-kompaniy.ru[/url] .