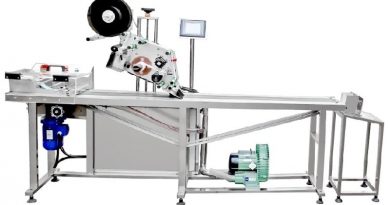

What Are The Inner Holders We Can Choose for Product Packaging?

When products are packaged, they not only need a packaging box, but most products also need to be lined inside the packaging box, that is, an inner holder. The inner support is an important link in the production of packaging boxes. Should an inner support be used? What kind of inner support should be used?

EVA material inner support

EVA materials are divided into three grades: Grade A, Grade B, Grade C. The thickness of EVA is required to be no less than 0.5mm and no more than 50mm. It is the most commonly used lining for hardcover boxes. It can be die-cut into any shape, and is also suitable for velvet fabric and paper mounting. EVA has a strong smell and can be deodorized after being exposed to the sun. The price is relatively high. It has the advantages of being moisture-proof, shock-proof, pressure-resistant, tough enough to be bent.

XPE material inner support

XPE is a raw particle foam with no additives and is a fully environmentally friendly material. The surface is smooth, the bubble holes are small, the density is high, the rebound is slightly hard. XPE is very similar to pearl cotton, with smooth texture and beautiful appearance, and is often used in tea boxes. XPE is not easily deformed, insulated and sealed, water-resistant, anti-corrosive, environmentally friendly and shock-proof. Suitable for packaging of hardware tools, electric tools, tea, cosmetics, fragile glass products, etc.

EPE material inner support

EPE is made of recycled polyethylene and has low environmental protection. The bubble holes are large and the density is low, so it will become thinner and softer with use. The price is more affordable than EVA and XPE. It has no smell and can be flocked, mounted on cardboard and special paper. EPE has the advantages of environmental protection, anti-static, thermal insulation, anti-collision, compression resistance, and anti-corrosion. Suitable for packaging of eggs, electronic appliances, glass products, fresh fruits and vegetables, etc.

Sponge material inner support

Sponges are made of wood cellulose fibers or foamed plastic polymers, which have strong tensile strength, uniform pores, high density, and can be flocked. Sponge has the advantages of good elasticity, good toughness, cushioning, shock absorption, heat insulation, and moisture resistance. Applicable to all types of packaging inner trays.

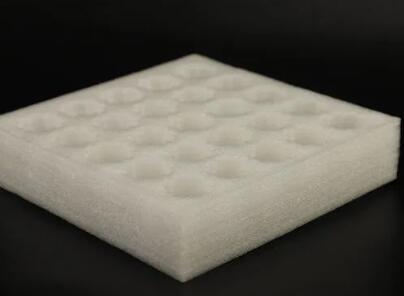

Foam material inner support

Foam is light, strong, shock-absorbing, has low moisture absorption, is easy to shape, and is cheap. Many wine boxes use foam as the inner support.

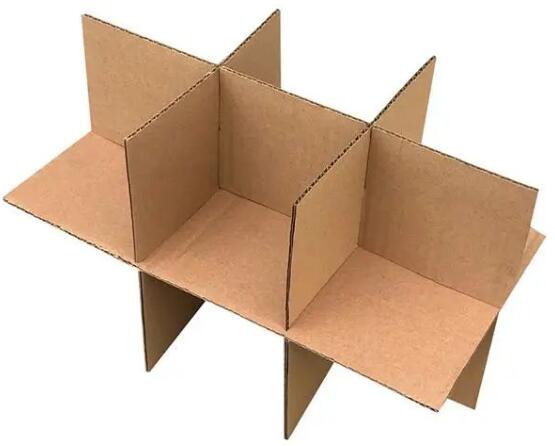

Corrugated board material inner support

Corrugated paper is a cardboard made of liner paper and corrugated corrugated paper formed by corrugating rod processing. The more common ones are three-layer corrugated corrugated A tile, B tile, C tile and E tile. Five-layer corrugated BE tiles, BC tiles, and AB tiles are distinguished according to the spacing of corrugated paper. Corrugated board has the advantages of anti-bending, anti-aging, high load-bearing strength, tensile, compression, tearing, and temperature resistance. Suitable for packaging in various industries such as electronics, food, medicine, etc.

Sheet-fed paper material inner holder

It is recommended to use high-weight paper above 250g. Generally, white cardboard, kraft paper, gold and silver cardboard are used to make the inner support. A variety of printing processes can be realized, suitable for food, electronic products, etc.

Cardboard material inner support

Using cardboard as the inner support is also a common way; the inner support of tea boxes and health care product gift boxes are also made of special paper mounted on gray boards and velvet cloth wrapped on gray boards.

Raffia

Raffia paper is made of pure cotton. As the name suggests, “paper” is the same special paper as the books we use. It can be torn into pieces and can be dampened by water. It imitates the original state of raffia. It is affordable and beautiful. If you have a variety of products and want to fit them all in one box, you can choose raffia paper. Raffia paper has good toughness, no peculiar smell, does not fade, and is rich in color. It is often used in various gift box packaging.

Pulp tray

Pulp refers to a fibrous material made from plant fiber as raw material through different processing methods. Pulp molding is a new packaging material for packaging paper trays, liners, filling materials and shock-proof linings. It is environmentally friendly and biodegradable and is a very popular packaging method today. Suitable for cosmetics, food, digital electronics and other fields.

Blister tray

Blister molding is a flat hard plastic piece that is heated and softened, then vacuum-adsorbed to the surface of the mold, and then cooled to form. Blister trays are the most common inner trays for packaging boxes. Suitable for electrical appliances, cosmetics, food, digital electronics and other fields.