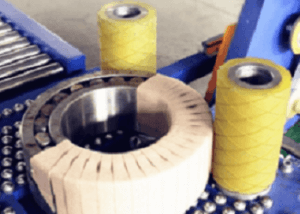

Bearing wrapping machine

This category of coil wrapping machines are designed for the use of packaging bearings specifically. The machines have both semi-automatic and fully automatic working modes which match with the customer’s need according to their capacity and requirement of the wrapping. The machine is applicable to use different packaging materials to pack the bearings including VCI tape. Fully automatic model is able to integrate with other machinery, finish the packaging after deburring, washing and demagnetization.

BH-CSB-300V

- Programmable PLC with automatic control system enhance the performance;

- Vertical structure with ring opening to the upwards, suitable for loading by hoist and crane;

- Multiple protective rollers ensure the safety of operation;

- Supportive rollers bear the heavy loads and drive the coils to rotate;

- Rotating ring carry the packaging material to wrap the coils by going through the coil eye;

- Material roll located at side of the wrapping station, suitable for larger film rolls;

- Applicable to different packaging materials including stretch wrap, composite paper, VCI tape….;

- Mainboard of the wrapping station adjustable to package different coils with variant sizes.

Config:

- Coil width: 100-300mm

- Coil ID: 300-600mm

- Coil OD: 500-800mm

- Max load: 1 tons

- Ring speed: 20-80rpm

- Roller speed: 2-4m/min

- Overlap ratio: 15%-80%

- Voltage: 380V, 50Hz, 3Ph

BH-CSB-H2

- Programmable PLC with automatic control system enhance the performance;

- Horizontal structure with a working height of 800mm, comfortable for operator to work;

- Multiple protective rollers ensure the safety of operation;

- Supportive rollers bear the heavy loads and drive the coils to rotate;

- Rotating ring carry the packaging material to wrap the coils by going through the coil eye;

- Material roll located on the rotating ring, suitable to use small rolls;

- Applicable to different packaging materials including stretch wrap, VCI tape….;

- Available to upgrade the wrapping station with a stroke to load by hoist or crane conveniently and package different coils with variant sizes.

Config:

- Coil width: 50-250mm

- Coil ID: 150-300mm

- Coil OD: 200-450mm

- Max load: 500Kg

- Ring speed: 20-100rpm

- Roller speed: 2-4m/min

- Overlap ratio: 15%-80%

- Voltage: 380V, 50Hz, 3Ph

BH-CSB-H20

- Programmable PLC with automatic control system enhance the performance;

- Horizontal structure with conveyors for integration with bearing processing machinery;

- Multiple protective rollers ensure the safety of operation;

- Supportive rollers bear the heavy loads and drive the coils to rotate;

- Rotating ring carry the packaging material to wrap the coils by going through the coil eye;

- Material roll located at side of the wrapping station, suitable to use large rolls;

- Applicable to different packaging materials including stretch wrap, composite paper, VCI tape….;

- Speed regulated by frequency converters to make consisted wrapping.

Config:

- Coil width: 100-200mm

- Coil ID: 200-300mm

- Coil OD: 300-450mm

- Max load: 500Kg

- Ring speed: 20-100rpm

- Roller speed: 2-4m/min

- Overlap ratio: 15%-80%

- Voltage: 380V, 50Hz, 3Ph

More accessories and special design or customization are acceptable, welcome to contact our team with your specific requirement and data information.

Details of the machines

Previous

Next