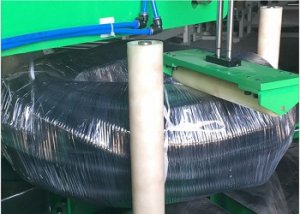

Hose & pipe coil wrapping machine

The hose coil wrapping machine is specifically to used for packaging hose and pipe bundles by stretch wrap. Widely used for manufacturers in irrigation and building material industries. Applicable to products like corrugated hose, solid wall pipe, irrigation pipe, dripping pipe…….The wrapped package can keep the products well protected to avoid the pollution from dust, rain….keep it clean and tidy for making the better sales.

BH-CSH-400V

- Programmable PLC with automatic control system enhance the performance;

- Vertical structure with the ring opening towards the downside, very convenient to operate;

- Multiple protective rollers ensure the safety of operation;

- Side rollers are adjustable for different widths by hand wheels;

- Rotating ring carry the packaging material to wrap the coils by going through the coil eye;

- Material roll located at side of the wrapping station, suitable for using larger rolls;

- Applicable to different packaging materials including stretch wrap, composite paper, coated PE film….;

- Mainboard of the wrapping station adjustable to package different coils with variant sizes.

Config:

- Coil width: 200-400mm

- Coil ID: 400-600mm

- Coil OD: 550-800mm

- Max load: 100Kg

- Ring speed: 20-80rpm

- Roller speed: 2-4m/min

- Overlap ratio: 15%-80%

- Voltage: 380V, 50Hz, 3Ph

BH-CSH-H2

- Programmable PLC with automatic control system enhance the performance;

- Horizontal structure with 800mm working height, comfortable for operator to do the work;

- Available to upgrade the wrapping station with a stroke, more convenient to load by hoist;

- Top pressing mechanism, adopt to keep the light coils stationary;

- Rotating ring carry the packaging material to wrap the coils by going through the coil eye;

- Material roll located at side of the wrapping station, suitable to use large film rolls;

- Applicable to different packaging materials including stretch wrap, composite paper, coated PE film….;

- Automatic error indication with lamp, notice the operator to solve problem in time.

Config:

- Coil width: 150-300mm

- Coil ID: 400-550mm

- Coil OD: 500-900mm

- Max load: 100Kg

- Ring speed: 20-70rpm

- Roller speed: 2-4m/min

- Overlap ratio: 15%-80%

- Voltage: 380V, 50Hz, 3Ph

More accessories and special design or customization are acceptable, welcome to contact our team with your specific requirement and data information.

Details of the machines

Previous

Next