How much Do you know about POF shrinkwrap Film?

POF is a shrinkwrap film primarily used for packaging products of both regular and irregular shapes. It has advantages such as being non-toxic and environmentally friendly, highly transparent, having a high shrinkage rate, excellent heat-sealing performance, high gloss, good toughness, strong tear resistance, and uniform heat shrinkage. Suitable for fully automatic high-speed heat shrink packaging machines, it is a replacement for traditional PVC heat shrink film.

How is it Made?

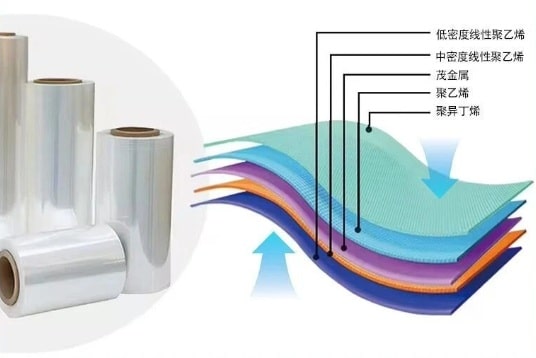

POF shrinkwrap film uses linear low-density polyethylene (LLDPE) and copolymer polypropylene (TPP, PPC) as the main raw materials, with necessary additives, and is processed through a five-layer co-extrusion blow molding process. Unlike traditional blow molding, which is unsuitable due to the poor tensile properties of PP in the molten state, a double-bubble process, also known internationally as the Prandtl process, is used instead. This process involves melt extrusion by machine, forming a primary film through a specially designed co-extrusion die, followed by quenching and secondary heating and stretching.

POF shrinkwrap film can be produced in various specifications according to application requirements. The typical thickness ranges from 12μm to 30μm, with commonly used thicknesses including 12μm, 15μm, 19μm, and 25μm. Width specifications depend on the packaging volume.

What does it Make from? And is it Safe to Use?

POF shrinkwrap film is made from LLDPE (linear low-density polyethylene), TPP (terpolymer polypropylene), PPC (binary copolymer polypropylene), and necessary functional additives such as lubricants, anti-blocking agents, and antistatic agents. These raw materials are all environmentally friendly and non-toxic, and will not produce toxic gases or odors during processing and product application. The product’s hygiene performance meets US FDA and USDA standards and can be used for food packaging.

What are the Characteristics of POF shrinkwrap Film?

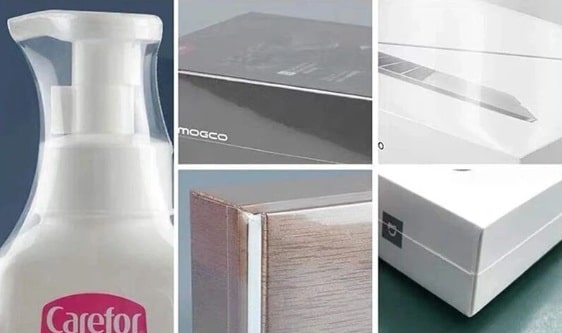

- High transparency and good gloss clearly showcase the product’s appearance, enhancing the sensory experience and highlighting high-end quality.

- High shrinkage rate, up to 75%, with good flexibility, suitable for packaging goods of any shape. Specially processed POF allows for controllable shrinkage force, meeting the shrinkage force requirements of different product packaging.

- Good sealing performance and high strength, suitable for manual, semi-automatic, and high-speed automatic packaging.

- Good cold resistance, maintaining flexibility without cracking at -50℃, suitable for storing and transporting goods in low-temperature environments.

- Environmentally friendly and non-toxic, complying with US FDA and USDA standards, and suitable for food packaging.

What’s the Prospect of POF shrinkwrap Film?

POF shrinkwrap film has a wide range of applications and a broad market prospect, offering advantages such as being environmentally friendly and non-toxic. Therefore, POF shrinkwrap film has received widespread attention from developed countries worldwide and has largely replaced PVC shrinkwrap film, becoming the mainstream product for heat shrink packaging materials. Currently, PVC shrinkwrap film still occupies a considerable market share in the heat shrink packaging market, but with the gradual increase in consumer packaging demands and the rapid development of POF shrinkwrap film production technology, it is foreseeable that the market prospect for POF shrinkwrap film is very broad.

https://shorturl.fm/QUAya

[url=https://rhsolutions1.in]Купить пластиковые окна на заказ в Москве[/url] — это отличный способ улучшить энергоэффективность вашего дома и повысить его комфорт.

Основное преимущество пластиковых окон заключается в их долговечности.

https://shorturl.fm/3LHNy