The best packaging methods for MDF

MDF is Medium Density Fiberboard, a construction and DIY board commonly used for cabinetry, furniture, and moldings. As a material, MDF is extremely versatile and cost-effective, making it an excellent choice for numerous projects. MDF is usually not used as a veneer alone, but with veneer or laminate veneer to give the impression of solid wood.

Because of MDF’s smoothness, it can be painted, cut, and shaped with ease, making it an ideal material for decorating DIY projects.

What is MDF made of?

MDF, a board rather than hardwood, is made by fusing fine wood fibers and glue together with heat and pressure. The resulting sheet is very strong and very easy to work with. Plus, it’s eco-friendly and made using reclaimed wood!

In addition to MDF, you can also get low-density fiberboard and high-density fiberboard. Low-density fiberboard, also known as particleboard, is made from smaller pieces of wood fused together. The result is cheaper, but also more difficult to machine because it is more likely to chip or break. HDF or hardboard is manufactured using more heat and pressure to create a stronger finish, however, this is reflected in the price. MDF is the perfect medium between these two materials – cost-effective, strong, durable and versatile.

How to Cut MDF Boards by Hand?

If you want to make straight cuts in MDF, you can use a hand-held cutting tool or a saw. Due to the high glue content of MDF, we recommend using carbide blades as this material will dull steel blades very quickly.

For curved-cut MDF, you can choose from a handheld multitool or a rotary tool with a multipurpose blade. However, if you want to create more detailed cutting or decorative patterns, jigsaw puzzles are always the best choice.

What’s the best packaging method for MDF?

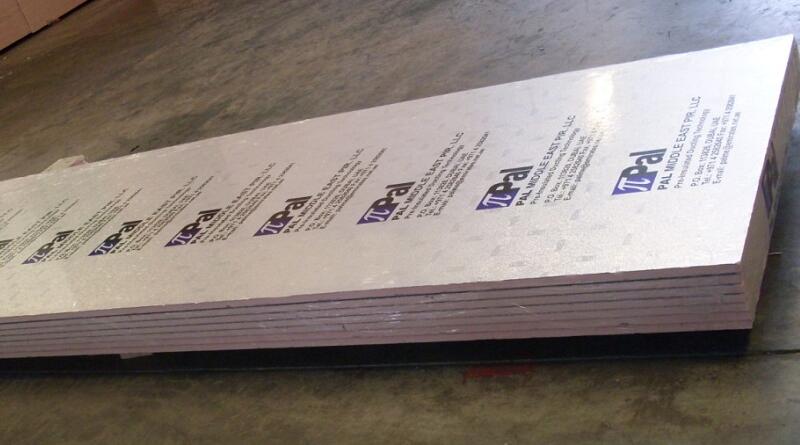

For MDF panels, the package should capable to prevent it from damages of dust, rain and moisture. The panel shrink wrap machine is the most ideal machine for making the packaging for MDF boards. This machine will make seals at the four sides of the panel, to fully wrap the panels without a leak. The shrink wrapped panels are packed inside tight package with good airtight function to prevent dust, rain and moisture. Keeps the MDF products with best function and quality.