What’s the Best packaging solution for Insulation Panels and boards ?

Modern buildings place great emphasis on thermal and sound insulation, and the use of insulation materials can make your home more comfortable and energy-efficient. There are many building insulation materials, including rigid foam insulation, spray foam insulation, fiberglass batt insulation, blown cellulose insulation, and more. Prefabricated insulation panels made from various insulation materials are becoming increasingly popular due to their ease of installation and ease of use. As manufacturers increase their output, packaging solutions for insulation panels are also gaining increasing attention. This article provides a comprehensive description and comparison of several insulation panel packaging options which BUHE Technology provides and the packaging machines required, hoping to be helpful.

Why package Insulation Panels?

There are three main reasons for packaging insulation panels:

- Packaging reduces contamination and damage during handling and storage, reducing scrap and defective products.

- Packaged products facilitate handling and transportation, making inventory counting easier and speeding up distribution.

- Packaged products enhance their appearance, creating a premium appearance compared to bulk products.

What packaging solutions are Suitable for Insulation Panels?

There are two suitable packaging options for insulation boards.

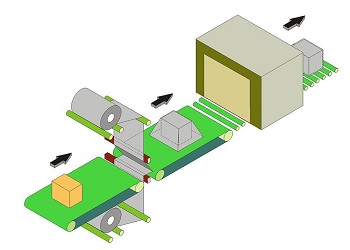

- Stretch wrapping, which requires a horizontal orbital stretch wrapping machine.

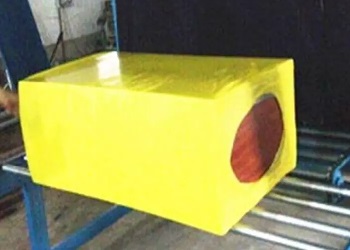

- Shrink wrapping, which requires a sleeve-type shrink wrapping machine.

What are the Differences between Stretch wrapping and Shrink wrapping?

- Stretch wrapping involves wrapping the insulation board with stretch film. While its appearance may be less attractive, the horizontal orbital stretch wrapping machine used has a wide range of product dimensions, making it suitable for packaging wider and longer boards and stacking them high.

- Shrink wrapping involves wrapping the board with PE film using a sleeve-type shrink wrapping machine, which then heat shrinks the board in a shrinking oven. Due to the limited width of the machine’s sealing blades, it is not suitable for packaging wider boards. However, it offers a better appearance, resulting in a tight, flat package.

Comparison between Horizontal orbital Stretch wrapping machines and Sleeve type sealing and Shrink wrapping machines:

| Size tolerance | Load ability | Package appearance | Package protection | Packing speed | |

| Orbital stretch wrapper | Good for big bundles | High | Bad | High | Low |

| Shrink wrapper | Good for small bundles | Low | Good | Medium | Very high |

Summary:

Stretch wrapping is preferred when packaging larger bundles or when stacking multiple layers of insulation boards. However, since the in-feed and out-feed conveyors of an orbital wrapping machine require a gap the width of the stretch film between them, it cannot be used with shorter panels. Heat shrink wrapping machines not only offer attractive packaging but also offer high speeds, making them suitable for packaging smaller, high-end insulation panels that demand a high level of aesthetic appeal.