How to Find the Root Cause of Poor Shrink Packaging Results?

When the shrink packaging of your product consistently fails to achieve the desired results, you might first suspect a problem with the shrink packaging machine. But have you considered that the issue might actually lie with your product? So, how do you pinpoint the problem? Carefully reading the machine’s user manual and inspecting several key components may help you identify the root cause of the packaging issue.

What aspects need to be checked?

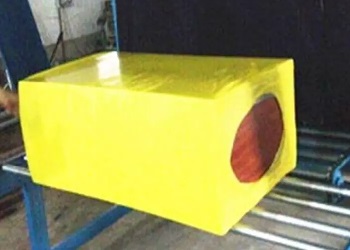

Heat Shrink Tunnel Size

The first machine component you need to check is the shrink tunnel. How big is it? More importantly, how big is it relative to your product? If your product is too large, it may be scratched or stuck when passing through the shrink tunnel. This can cause the film to melt and perforate;

Shrink Temperature

What is the temperature of the shrink tunnel (shrink oven)? If the temperature is not high enough, your product will not seal and shrink properly. Furthermore, a shrink tunnel that is too hot can also cause problems, as some products cannot withstand high temperatures. If your product comes out of the shrink tunnel melted or damaged, you need to test it to determine its heat resistance;

The Shrink Wrapped Products

Is your product unusually shaped, too large, or too small?

Your product will also affect the effectiveness of shrink packaging in several ways. Products that do not meet specifications may not pass smoothly through the shrink packaging machine. You first need to check if the machine can handle your product, verifying its actual weight and dimensions, and comparing them to the size requirements specified in the machine’s user manual to determine if your product can pass through the machine;

Conveyors

You should be aware that there are many types of conveyors. Some types of conveyors are incompatible with certain products or films.

For example, self-propelled roller conveyors are not suitable for polyethylene film. Polyethylene film is sticky and easily adheres to the rollers, potentially causing tearing and other problems. If you are using polyethylene film, consider using a mesh conveyor or a non-rotating roller conveyor to avoid sticking. If your product is moving continuously on the conveyor belt, you may need to install some guide rails to keep it centered and stable;

Materials

What kind of film are you using to package your product? Your machine may be incompatible with the size or specifications you are using. Furthermore, your product may also be incompatible with the film you are using.

Chemicals in some products, such as fragrances, may react uniquely with the film, thus reducing the effectiveness of shrink packaging. Before use, please ensure that the type of film you are using is compatible with your machine, conveyor belt, and product.

Summary

Shrink packaging may be affected by one or more factors, such as the type or size of the shrink packaging machine, the shrink packaging material, or even the product itself. Incompatibility between the product and machine, the packaging material, excessively large/small size, or inadequate supporting facilities can all lead to unsatisfactory shrink packaging results. We need to check each factor individually to find the root cause of the problem.

Thinking of putting some bets down on suncitybetvn. Seems legit. Anyone else use them? Any recommendations on what to bet on?

The platform excels in customer service, offering various ways to reach support.

app 888starz [url=http://888starz-eng.com/pt/download-app/]https://888starz-eng.com/pt/download-app/[/url]