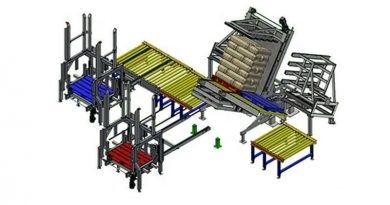

Pile Turner-New equipment for Flipping stacks of Printing paper

A paper pile turner, also known as a pile reversing machine or paper sorting machine, primarily removes dust, sorts, loosens, and turns paper piles. This device can sort paper before printing and flip it 180 degrees to facilitate printing on the reverse side of the paper for duplex printing. This product can effectively improve production efficiency, save labor, reduce production costs, and enhance print quality.

The machine consists of eight components: a base, a turning unit, a clamping plate, an adjustable stop, an air blowing system, a vibration system, a hydraulic system, and an electrical control system.

The turning body can flip up, down, and rotate.

The base supports the turning body and is tiltable.

The upper and lower clamps clamp the paper stack, which is guided by linear guides on the turning platform and opened and closed by a hydraulic cylinder-driven chain.

An adjustable stop gauge is installed between the two clamps of the turning body to position the paper stack’s edge to accommodate paper size.

The air blowing system includes a fan, nozzle movement mechanism, and air volume control system.

The vibration system includes a vibration motor, vibration platform, and vibration control system.

The imported hydraulic station effectively controls pressure and flow, ensuring unobstructed oil flow for smooth, safe, and reliable operation.

All electrical components are from renowned brands such as Omron, Schneider, Izumi, and Delta, ensuring stable performance and a long service life.

879hv5

починка бойлера [url=https://master-remonta-boylerov.ru/]https://master-remonta-boylerov.ru/[/url]

Купить шарики с гелием — это простое и эффектное решение для любого мероприятия. Они добавляют радости и веселья, создавая уникальную атмосферу.

[url=https://shariki-s-geliem.ru/]Шарики с гелием купить[/url] для вашего праздника!

Выбор гелиевых шариков очень разнообразен. Эти шарики могут быть как с изображениями, так и одноцветными, в зависимости от вашего предпочтения.

Шарики с гелием доступны как в офлайн-магазинах, так и в интернет-магазинах. Онлайн-покупка часто бывает более удобной и быстрой.

Обратите внимание на правила безопасности при использовании шариков с гелием. Следите за тем, чтобы шарики не оказывались вблизи воды и всегда были под контролем.

Доставка тюльпанов — это прекрасный способ порадовать близких. Эти цветы символизируют весну и радость. Тюльпаны в качестве подарка — это всегда уместно и приятно.

Закажите [url=https://tyulpany-msk.ru/]тюльпаны недорого и радуйте своих близких свежими цветами![/url]

Тюльпаны бывают разных сортов и оттенков. Каждый сорт имеет свою уникальную красоту и характер. Выбор подходящего букета для конкретного случая становится простым.

Услуга онлайн-доставки тюльпанов становится все более популярной. Преимущества интернет-заказа очевидны — экономия времени и усилий. Различные компании предлагают услуги по доставке тюльпанов на дом.

Быстрая доставка тюльпанов позволяет удивить близких в самый нужный момент. Заказав доставку в нужный момент, вы сделаете свой подарок особенным. Вы можете дополнить букет тюльпанов красивой упаковкой и открыткой.