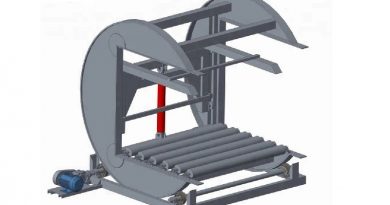

Fully automatic inline pallet inverting and changing machine

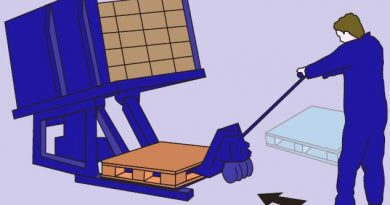

In high throughput manufacturing plants, automatic production line with high speed can make every workers exhausted. So automation is very important for lowering the labour intensity as the goods are handling by the conveyors.

When talking about pallet inverter and pallet changing machines, sometimes users want their pallets to be exchanged in an automatic system. This fully automatic inline pallet changing system by Toppy is just the right solution to make their dreams come true.

In the continuous operation, pallets can be changed and rotated gently. The automatic steps will reduce the burden for the workers to replace pallets.

The loads are forwarded on conveyors and moving into the pallet inverter, then it will clamp by the machine and then rotate to 110°. Old pallets will release by an independent plate and a new pallet will move into the pallet inverter by conveyors and will be centered and fixed. After this process, the load will then stand upside down.

This inline pallet inverter has lots of benefits:

- Automatic 110° rotation;

- Suitable for many different pallet sizes and qualities;

- Ideal for robust goods, particularly bags;

- Reliable with damaged pallets;

- Available to integrate with other conveyors;

- Low-maintenance, low-noise and leakage-free.