Comparison of Semi-automatic and Fully Automatic Turntable Pallet Stretch Film Wrapping Machine

Does your warehouse or workshop need to wrap a large number of goods loaded on pallets every day? The turntable pallet stretch film wrapping machine may be an option worth considering because it can help you complete the stretch film wrapping faster and efficiently. Avoid injuries such as back injuries caused by heavy work during manual wrapping.

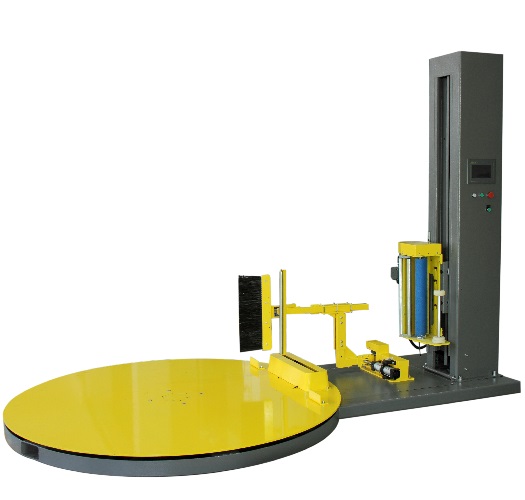

The technical principle of this machine is to rotate the pallet goods on the turntable while wrapping the stretch film onto the pallet. The film roll is loaded on the film bracket, and the bracket moves up and down to complete the packaging of the entire goods.

Specifically, there are two types of turntable pallet stretch film wrapping machines: semi-automatic and fully automatic. Each model has its advantages and disadvantages. We will introduce it to you in detail below:

Semi-automatic turntable pallet wrapping machine

The semi-automatic turntable pallet stretch wrapping machine requires operator operation. The machine will automatically wrap the pallet, but loading and unloading the pallet requires the operator to use a forklift or pallet truck to complete. In addition, the operator needs to press the start button before starting to wrap.

After wrapping, the film still needs to be cut manually, but some models may be equipped with an automatic film cutter to automatically load, clamp and cut the film. Although the semi-automatic wrapping machine is not fully automatic, the manual wrapping process is time-consuming and heavy. Therefore, the semi-automatic model is still popular because it can provide great help and increase your production capacity. In addition, the machine has a pre-stretching function, which saves more material than manual wrapping and makes the wrapping package tighter.

The general speed of the semi-automatic model is about 10-30 pallets per hour, which is an ideal choice for increasing loading capacity, reducing product damage and saving packaging material costs.

Fully automatic turntable pallet stretch wrapping machine

As the name of this model shows, this model is unmanned and does not require a dedicated operator. This model is integrated with the palletizer or assembly packaging line through a conveyor belt. When the machine detects the arrival of the pallet, it starts the conveyor belt and wraps it at the turntable position. After the packaging is completed, the film clamp automatically clamps and cuts the film, and each step is controlled by the PLC program without any operator.

Conclusion

After introducing all the advantages of these two models, we can see that choosing a semi-automatic turntable pallet stretch wrapping machine is ideal for small business owners who have fewer quantities and want to reduce equipment expenditures. But large factories and warehouses may need to be equipped with a fully automatic turntable pallet stretch wrapping machine. Because they also have existing assembly or packaging production lines, integrating the pallet wrapping machine with other mechanical equipment can automate the entire process. This not only increases production capacity and working time, but also saves a lot of labor costs and improves the reliability of the production line.

o8fdcn