Intelligent warehousing terminal material handling system

“Intelligent warehousing terminal material handling system” is an integrated load handling solution by both mechanical, electric, hydraulic and photoelectrical, IT and other technologies developed by modern technology to realize the automation of bagged goods delivery and maximize the efficiency of smart warehouses or three-dimensional warehouses. Independent innovation research and development of automation equipment. The system can carry out stockpiling, automatic transportation, package dismantling, empty pallet recovery, palletless loading, etc. , forklift with ejector, pedaling platform, control system, etc. constitute the cargo conveying system, pallet conversion system, transfer system, PLC control system, etc.

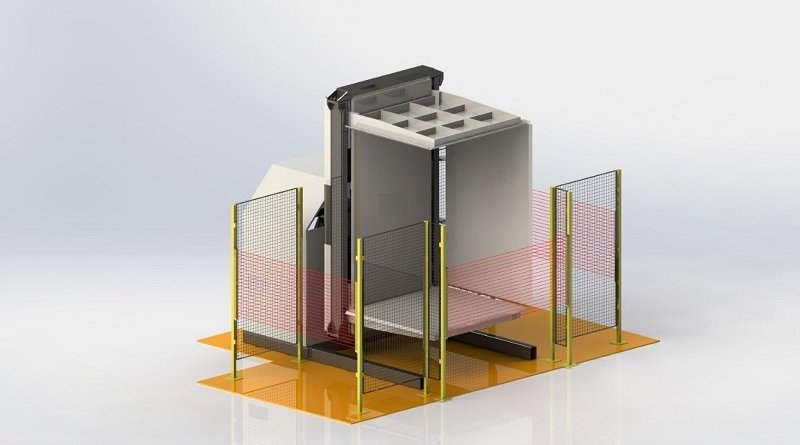

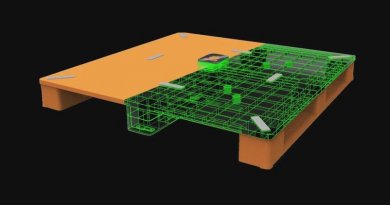

The system is connected to the vertical warehouse through the roller table. When the roller table senses that the goods are in place, the system performs stocking or shipping processing according to the shipping status. After the delivery process is started, the stack of goods is transported to the rotating platform through the roller table and the transfer machine, and the pallet inverter rotates 180 degrees to turn the stack of goods over, so that the goods fall on the comb teeth of the pallet inverter, and the pallet falls on above the goods. At this time, the forklift takes out the empty pallet above the goods and transfers it to the pallet recovery line, and the pallet recovery line performs stacking process on the pallet. A forklift with an ejector takes out the goods on the comb teeth, and loads the truck through the pedal platform. The material terminal handling system is controlled by a programmable PLC system, so that the system itself can perform manual, automatic and maintenance operations. Complete functions and easy control.

This project is the key equipment to realize the automatic loading and delivery of bagged goods, and realize the automation, efficiency and safety of the delivery of the bagged industry smart warehousing. The project fills the domestic gap, and the technical level is in the leading position.

Features:

(1) According to the needs of different customer working conditions, the applicable material terminal handling system can be customized for customers. It can not only realize the seamless connection with the modern three-dimensional warehouse by connecting with the roller table line of the three-dimensional warehouse, but also can set up a system independently to realize the loading of the vehicle by the machine instead of the person, and the replacement by machine, which improves the work efficiency and reduces the cost, and is safe and reliable.

(2) At the front end of the delivery area, through the functions of clamping, flipping, opening, and lifting of the pallet flipping system, the rapid separation of goods and pallets is realized, and the pallet replacement efficiency is high. The goods are delivered to containers or large trucks. Empty pallets are recycled through roller conveyor lines, forklift and palletizers. They are automatically recycled and returned to designated locations for use. The efficiency of pallet recycling is high.

(3) The terminal material handling system is controlled by PLC, which can realize single-machine control, multi-machine joint control or network operation with the smart warehouse, providing users with efficient and controllable automatic control equipment, and providing a perfect modern network for industrial development.

(4) The system adopts several groups of safety photoelectric induction and mechanical safety interlocking devices to ensure the safety performance of the equipment.