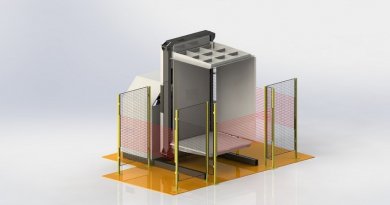

Non pallet transfer artifact

The push-puller is designed specifically for the handling and stacking of goods without pallets. There is no need to carry traditional pallets by using this machine, and there is no need to unstack the goods. For the handling or loading of bagged goods or boxed goods, the use of the push-pullers (supplemented by sliding plates) machine improves the efficiency of on-site operations than other ways, improves the space utilization rate of containers, and reduces the loss of pallets, transportation and labor. At the same time, with the three characteristics of convenient operation of this equipment, stable operation and controllable cost, this product has been widely used in petrochemical chemical industry, pharmaceutical plants, logistics system, grain and oil production, household appliances and other industries that require palletless handling.

According to the customer’s use or on-site working conditions, the push-puller machine can be designed as a sliding plate retaining type (the sliding plate is not pushed away with the goods) or the sliding plate non-retaining type (the sliding plate is pushed away with the goods), with side shift function or without this function, as well as with the function of voltage regulation, etc., to meet the actual operation needs of different customers.

Push-puller machine’s process functions and advantages:

- Reasonable overall structure, wide field of vision, dexterity and easy operation;

- The pallet-free handling or loading of goods is carried out with the help of the skateboard, which partially solves the problem of pallet stacking and storage which taking up a lot of space;

- The fork plate is durable and smooth, which can avoid damage to the contact part of the skateboard during operation;

- The design of hydraulic components is reasonable, so that the hydraulic system is well protected and has a long service life;

- The linkage mechanism of the ejector is scientifically designed, with good strength, strong rigidity and good synchronization.