Why is Stretch Hood Film so Expensive?

Among all packaging materials, stretch hood film has always been the most difficult and expensive packaging material. So why is stretch hood film so advanced? We need to dissect and analyze its application scenarios, development history and industry status one by one.

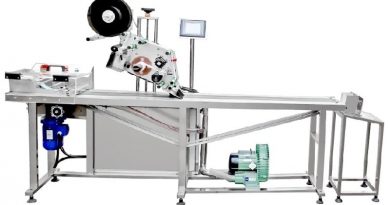

First of all, in order to get the maximum profit on the stretch hood film packaging line, we should use high-quality stretch hood film packaging equipment, but if there is no suitable film on the production line, many failures will occur (such as machine shutdown and film tearing, etc.), thus causing many expensive manual operations and the loss of the tubular elastic sleeve, affecting product circulation.

Because of the need to meet both strength and toughness requirements, stretch hood film are usually three-layer structures. The inner and outer layers are required to have good puncture resistance and tear resistance, while also ensuring a certain degree of transparency and sealing; the middle layer needs to have high elasticity. According to statistics, currently, the thickness of the stretch hood film on the market is 80-140μm, the blow-up ratio is (2.5-2.8):1, the mass of the film tube is about 900g, and the thickness ratio of the outer layer, middle layer and inner layer is 1 :3:1 mostly. The above indicators can also be adjusted according to needs.

The NexxstarTM brand series of resins launched by ExxonMobil Chemical Company of the United States has the advantages of low cost, high toughness, and good optical properties. The company applies it in a three-layer co-extrusion blown film processing system, in which the middle layer uses EscoreneTM Ultra ethylene-vinyl acetate copolymer (EVA), and the inner and outer layers use ExceedTM metallocene linear low-density polyethylene (mLLDPE). , the film layer distribution is 1:3:1, and the film thickness depends on the load size and pallet size. EVA can make the film have excellent elasticity and heat sealing fastness, while mLLDPE can give the film wear resistance, puncture resistance and high transparency. For a softer film with significantly improved strength and a wider operating range, Vistamaxx™ propylene-based elastomer can be added to the formulation. VistamaxxTM propylene-based elastomer has performance advantages such as high tear resistance and puncture resistance as well as high resilience. Adding a stretch hood film core layer facilitates film switching for different casing applications. The addition of VistamaxxTM 3020FL enables the film to have high clamping force, wide operating range, and high puncture and tear resistance, which is called a multifunctional stretch hood. If higher elasticity and superior tear and puncture resistance are required, the content of VistamaxxTM 3020FL needs to be further increased, which is called a high-tenacity stretch hood, and also improves low-temperature stretchability. The highly elastic soft film is added with VistamaxxTM 6102FL, which can maintain excellent resilience and good puncture resistance. It is called a soft stretch hood and has lower cornering force. Ohlsson et al. developed a vinyl polymer. The composition of the polymer used in the stretch hood film is: the core layer uses the polymer, and the composition of the inner and outer layers is allowed to be different, but the mass fraction of linear low-density polyethylene is at least 60%.

The Dow Chemical Company believes that the friction coefficient of the stretch hood must be low enough so that the elastic hood can be applied without wrinkling and tearing. On the contrary, if the friction coefficient of the elastic hood is too high, it will be difficult to detach from the robotic arm, causing the elastic hood to be excessively stretched in the vertical direction. The Dow Chemical Company uses DOWLEXTM polyethylene resin and ELITETM reinforced polyethylene resin as the surface layer of the stretch hood film. Mandare et al. developed a three-layer co-extruded film for stretch hood film packaging. The film thickness is at least about 76.2 μm, in which the surface layer mass does not exceed 50% of the total film mass, and the core layer contains at least 50% ethylene by mass fraction. Based polymers (such as Dow Chemical Company’s VERSIFYTM elastomer, Canadian Nova Chemical Company’s SUPPASSTM, ExxonMobil Chemical Company’s Vista-maxxTM, etc.). Bensason et al. developed a three-layer co-extruded stretch hood film formula based on ultra-low density polyethylene (ULDPE) with a density not exceeding 0.920g/cm3. The core layer is ULDPE or low-density polyethylene (LDPE)/EVA, where the density of ULDPE is 0.900-0.920g/cm3, and the mass fraction is not less than 50%; the surface layer is ULDPE and LDPE, where the weight percentage of ULDPE is not less than 50%.

Stretch Hood Film Market

In 2011, the global stretch hood film market capacity was about 250kt/a. Europe is the main market, followed by North America and other regions. The application volume in Asia-Pacific is relatively small, but it has a high growth rate. In terms of application fields, 25% of stretch hood films are currently used for protection and display (such as food, beverages and electrical appliances, etc.). This application field requires high transparency, low extrusion force, high strength and other properties; 35% of the stretch hood film is used for heavy-packing pallets. This part requires a certain clamping force and pallet stability, and has a certain Physical properties; 40% stretch hood film is used as dustproof and rainproof cover for brick building materials. This field requires high puncture resistance and tear resistance. Stretch hood film has penetrated into the construction and heavy-duty packaging bags fields to the greatest extent in Europe and the United States, and its main growth is expected to be in the fields of food, beverages and electrical appliances. The average annual growth rate of stretch hood film is about 20%, and most of it is used to replace shrink packaging in Europe and cardboard packaging in North America and Asia. This also indicates that stretch hood film packaging will become the development trend and improvement direction of the packaging market.

So, the high price of stretch hood film is resulted both by the high level of film manufacturing and less developed market. As the time goes, more people could be interested into this new packaging material and more new technology will bring solutions to the industry to make the costs go down.