What is Palletpal and How Does It Work as A Pallet Positioner?

Spring actuated palletpal is also called as mechanical pallet leveler or pallet level loader. A pallet level loader is a positioner, not a lifting table. As a pallet positioner, its function is different from that of a lifting table. It responds to the load rather than the operator. The unit has no controls and the operator does not have to do anything other than complete the job of loading and unloading pallets. The spring configuration of the pallet loader is actually deciding for him what height the top of the load will be. We achieve this through a series of calibrated springs.

We ship with three different springs. In a combination of three springs, you can have four load combinations. We set the load combination based on the height of the pallet and the weight of the pallet. Once you understand both, you can set up the correct spring combination. Under suitable height conditions, the operator can work continuously with a straight back and will not feel fatigue. In the long run, the use of pallet loaders also reduces the chances of labor-related accidents. The Palletpal has a manual rotating turntable that allows for near-side loading so the operator does not have to walk around the pallet. Without the use of a pallet level loader, approximately 40% of pallet loading and unloading time is wasted walking around pallets, so the turntable allows for near-side loading, and the operator can stand in one position to complete the work, greatly improving cargo handling efficiency.

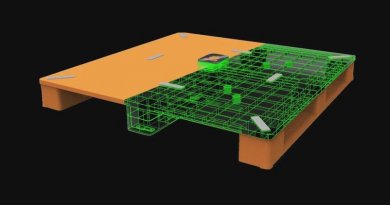

Pallet level loaders feature heavy-duty tubular legs that keep the platform stable and rigid throughout its range of travel. The unit is equipped with a damper that allows the load to drop. Therefore, heavy loads, such as cement bags, dropped onto the pallet will not bounce around. The unit also features built-in forklift slots in the base, allowing you to access it with a forklift and easily move the unit to another location. There is a leveling foot device at each of its four corners, which is suitable for working on uneven ground. The operator can use the leveling feet to adjust the unit higher or lower.

Another advantage of the pallet level loader is that there are no connections required, no connections for compressed air, no connections for electricity. Once the spring range is set, it stays that way forever.

We know that in most cases, using a pallet level loader not only makes the operator’s job easier, but also increases the speed of the job by about 40%. Therefore, the palletpal not only brings us a more convenient way of working, but also saves us the labor costs and investment related to cargo handling, loading and unloading.

Pingback: How to Load A Pallet Quickly by Using PalletPal Level Loader? - Pallet inverter