What is pre-stretch of pallet wrapping machine?

POST-STRETCH VS PRE-STRETCH:

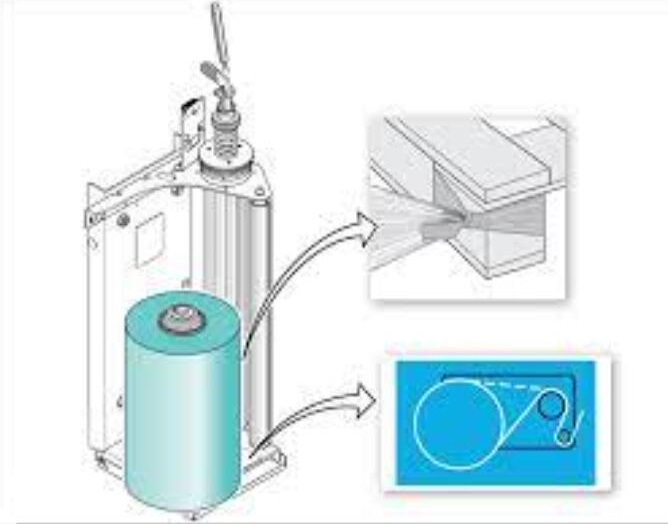

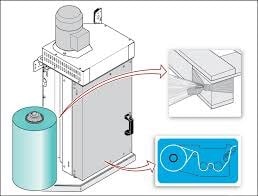

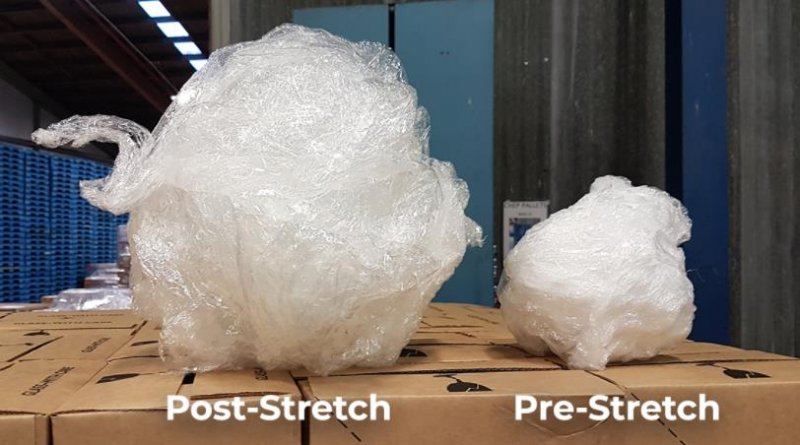

There are post-stretch film carriage and pre-stretch film carriages on the pallet stretch wrapper machines. On the post-stretch film carriage, the percentage of stretching is very little. A roll of one kilometer film is almost only wraps 1.2 kilometer as we estimated. But if it’s on a pre-stretch film carriage, the situation of film consumption is very different. The pre-stretch film carriage is able to stretch one kilometer stretch wrap to three kilometers or even longer length, greatly reduce the consumption of the wrapping materials.

So if the post-stretch pallet wrapper and pre-stretch pallet wrapper are running side-by-side, the pre-stretch pallet wrapping machine can wrap 3 times as many pallets as the post-stretch pallet wrapper can wrap with the exact same amount of stretch wrap materials. It helps you to save a lot of costs in the packaging materials in the long term.

Different pre-stretch film carriage can realize different levels of pre-stretching ratio. The standard film carriage of us is capable to make 250% pre-stretching, but we also can customize the wrap heads with different pre-stretch range which from 200% to 300% depending on your ideal wrapping and requirement. There are actually two ways of calculations of pre-stretch. With a pre-stretch film carriage, the pre-stretch percentage is how much it increased the length of your stretch film by. So with a 250% pre-stretch film carriage, it means one-kilometer stretch film will allow you to wrap as long as 2.5 kilometres.

The biggest feature of the pre-stretch wrap heads is it can save you a lot of costs as it pre-stretches the film to a longer length, so the total consumption of the wrap film material is lowered and reduce much of the costs. But besides expanding the stretch film length, the pre-stretch film carriage also can stop the neckdown problem. So what is a neckdown problem? Neckdown problem means the narrowing of stretch-film when it’s stretching around a load or pallet.

This is the potential problem when using the post-stretch film carriage, as the stretch film stretches between the pallet and pallet wrapping machine, the film becomes longer and thinner but lose its original width. The width losing means every round of wrapping needs to be closer together, that comes as more stretch film material is needed for making a securely wrapped package. From our experience, the conventional 500mm wide stretch wrap could end up being 350mm wide only when wrapped on the palletized loads.

But the pre-stretch film carriage is a good way to avoid the neckdown problem. The pre-stretching of the plastic film is powered by electrical motor within the wrap head, this ensures the pre-stretched film is as wide as when it comes off from the film rolls. This promise of film width means we can minimize the wrapping cycles and save the costs spend on the wrapping materials.

Pingback: Why there is still Post stretch pallet wrapper? - Pallet inverter