The packaging ways for modular furniture

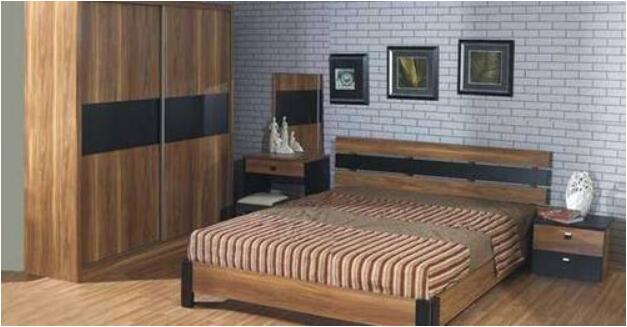

With the increase in the export volume of furniture in bulk packaging, furniture that needs to be transported over long distances needs to be transported more and more to consider the cost. Regardless of the relationship between the convenience of handling and the cost, only the container space occupied by the whole container can keep the transportation cost high. Bulk packaging can save space, so it is used more and more. The body of the panel furniture is generally made of melamine veneer particleboard, which mainly plays the role of separating the space and supporting the shelving items. This creates conditions for the stacking and packaging of sheets, and the sheets of the same size can be packed in one package as much as possible. During packaging, loose cabinets of the same size (the panels that can be used to form the cabinet) can be sorted and stacked together. Put the appropriate side-sealed carton according to the size of various cabinets, and seal the carton with tape.

Door panel packaging technology The door panel packaging of furniture should be packaged in a side-sealed carton. First, place the product on the carton and seal it with saddle stitches at the side opening. This type of carton is mainly used to pack flat furniture, such as mirrors, partitions, glass, beds, etc. The door panel is an important part of furniture. The surface of the door panel of some cabinets is not the same material as the cabinet itself. Most of the cabinet door panels are more complicated and costly to process than the cabinet body. The door panel is an important standard to reflect the gorgeousness of furniture. Therefore, in the process of packaging the door panels, pay attention to the following points: A. The door panels must be packaged separately, because some door panels are painted, and if they are packaged with the kitchen cabinet, they will scratch the door panels and cause huge losses. B. Before packing, carefully check the door panel, and then install the appropriate foam board around the door panel. Check that the installation is secure. C. Put the door panel into a suitable side-sealed carton, and seal the carton around with tape.

The packaging of accessories is also a very important content in the packaging of panel furniture. It can be divided into four categories: ultra-long parts packaging, fragile parts packaging, small parts packaging and large kitchen appliance packaging.

Extra-long parts packaging furniture will use some super-long parts, such as the base line, the upper part of the hanging cabinet, the eyebrow line of the lower part of the hanging cabinet, etc. When packing these parts, it is necessary to pack as many slender parts as possible, and individual parts that are easily scratched need to be packed with a layer of pearl cotton and then packed with corrugated paper. The corrugated paper is protected by right-angle paper corners with a certain hardness. Finally, use strapping tape or transparent glue to bind every 40mm or so to ensure that the package is not scattered. Seal the ends to prevent the shorter pieces from slipping out of the package.

Fragile parts packaging There are many types of fragile parts, the most important ones are artificial stone and glass panels and glass door panels. Since artificial stone countertops are integrally formed at one time, they are generally not divided and transported. It has the characteristics of large volume and large mass, and it is relatively inconvenient to carry. Artificial stone countertops have a certain brittleness and are afraid of being bumped by sharp objects. Therefore, artificial stone packaging is mostly made of cardboard boxes with sky and earth lids, and the packaging is reinforced with a wooden frame. A very thick sponge pad is often used as a buffer between the wooden frame and the carton. Glass panels and glass door panels need to choose wooden boxes according to the area of the glass. In the trellis box, padded with padding and filled with glass. When loading glass, pay attention to keeping the loading direction of the glass parallel to the length of the box. The edges of the glass should be neat; the glass that needs liner paper should be laid in time according to the regulations, and the cover should be sealed after the liner is filled, and the four corners of the box should be reinforced with steel tapes and nailed firmly. In the package of the combination box, it is necessary to put an appropriate amount of sponge strips or other cushions with better cushioning properties on the plug. Load the glass tightly, and then fasten the bottom and cover of the box. When the bottom (cover) help plate and the plug help plate are about to be tightened, the steel belt should be tightened, and the nail belt should be tightened firmly.

Pingback: What does packaging mean to furniture industry? - Pallet inverter

Pingback: viagra sale

Pingback: scholarship essay writing help

Pingback: essay help chat room

Pingback: help me write a narrative essay