Different methods and equipment for cutting aluminum profiles

Compared with the semi-automatic aluminum cutting machine, the manual aluminum cutting machine is easy to operate. It needs to manually press down the machine head to cut the material, and it is sold in hardware tool stores in the market.

Semi-automatic aluminum cutting machine includes gas-oil conversion type and hydraulic type, which are produced by professional aluminum cutting machine manufacturers. The size is small, the precision of the hydraulic type is poor, and the size of the cutting material is large. The semi-automatic aluminum cutting machine only needs to manually give the machine a signal, and the machine will automatically complete the clamping and cutting actions. The signal-giving devices include button type and pneumatic pedal type. , Electric pedal.

Fully automatic aluminum cutting machine is controlled by PLC programmable memory for each component and workpiece of the machine. It only needs to be set once, and then the switch is turned on. The machine will automatically complete functions such as clamping, cutting, feeding, and counting. Good efficiency and machining accuracy.

Function and use:

- The head of the manual cutting machine can turn left and right, and can cut 45-degree angles. The cutting accuracy is poor, and it is suitable for the aluminum door and window industry and the aluminum material cutting work that does not require high precision.

- Semi-automatic air-oil conversion high-speed aluminum cutting machine, adopts tungsten steel circular saw blade for cutting, the spindle speed is 3200 rpm, uses air-oil conversion as the machine feeding and pressing power, hidden saw blade, the saw blade cuts from the bottom to the top , Automatic material pressing and cutting, machine automatic oil spray mist lubrication, cutting material cross-section smooth without burrs, high precision, single or multiple cutting, simple and safe operation, suitable for cutting and blanking of various aluminum products, aluminum rods, aluminum tubes , aluminum strips and other aluminum profile sawing blanking. Semi-automatic hydraulic aluminum cutting machine, the structure of the machine is rough, the machine uses hydraulic pressure as the feeding power, the saw blade performs parallel feeding action, the section accuracy of the cutting material is poor, and the cutting material is large in size, suitable for rough cutting of aluminum materials.

- Fully automatic aluminum cutting machine, suitable for small pieces of aluminum, large cutting volume, cutting work with high precision requirements, small pieces of aluminum can be cut in bundles, and multiple pieces can be cut at one time, with high efficiency. The machine has feeding, clamps, Positioning and other functions are controlled by PLC to realize automatic cutting work. The tungsten steel circular saw blade is used for cutting. The saw blade rotates at a speed of 3200 revolutions per minute. The section of the cutting material is smooth and burr-free. It is suitable for the cutting precision requirements of various aluminum products. Such as heat sink aluminum, U disk MP3 aluminum shell, aluminum tube, aluminum rod, aluminum alloy material cutting and sawing.

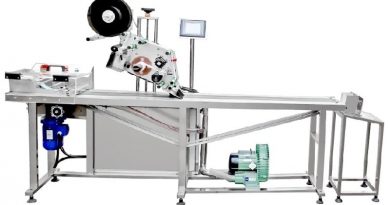

BUHE provides orbital wrapping machine for aluminum profile bundling and packaging

This orbital wrapper is a special equipment for wrapping a layer of protective film on the surface of aluminum profiles. There are three specifications: four-sided wrapping, reinforced wrapping, and multi-layer wrapping. It has the following characteristics: it can improve work efficiency and will not affect the surface quality of aluminum products.