What is a labeling machine?

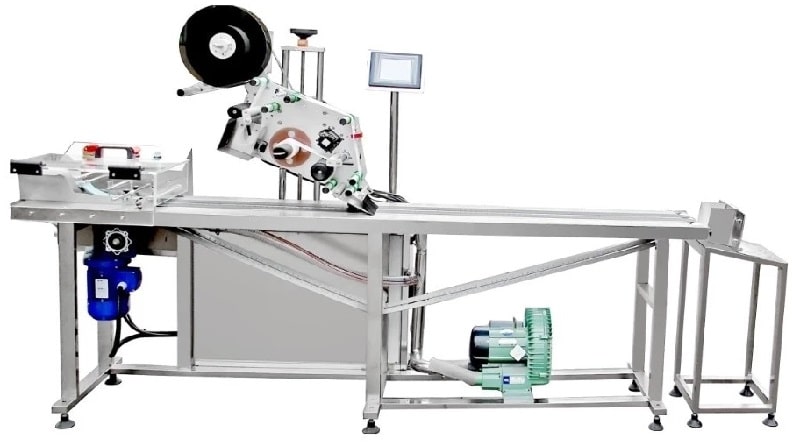

The labeling machine is a device that sticks paper or metal foil labels on specified packaging containers with glue. Labeling machines are an integral part of modern packaging. At present, the types of labeling machines produced in China are gradually increasing, and the technical level has also been greatly improved. It has changed from the backward situation of manual and semi-automatic labeling to the pattern of automated high-speed labeling machines occupying the vast market.

Type of labeling machine:

- Planar labeling machine realizes labeling and filming on the upper plane and upper arc surface of workpieces, such as boxes, books, plastic cases, etc. There are two methods of rolling and suction, and the selection is mainly based on efficiency, precision and air bubble requirements.

- The round bottle labeling machine realizes labeling or filming on the circumferential surface of cylindrical and conical products, such as glass bottles, plastic bottles, etc., and can realize functions such as circumference, semi-circle, circumference double-sided, circumference positioning and labeling, mainly including vertical labeling and horizontal labeling.

- The side type labeling machine realizes labeling or filming on the side plane and side arc surface of the workpiece, such as cosmetic flat bottles, square boxes, etc., and can be equipped with round bottle labeling equipment to realize round bottle labeling at the same time.

The working principle of the labeling machine:

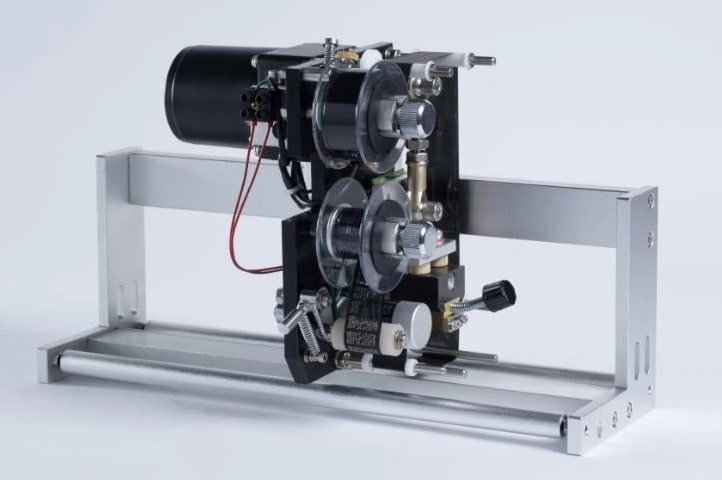

The working process begins with boxes being fed to the labeling machine at a constant speed on the conveyor belt. The mechanical fixture separates the boxes by a fixed distance and pushes the boxes along the direction of the conveyor belt. The mechanical system of the labeling machine includes a driving wheel, a labeling wheel, and a reel. The driving wheel intermittently drags the label tape to move, the label tape is pulled out from the reel, and at the same time passes through the labeling wheel. The labeling wheel will press the label tape on the box. An open-loop displacement control is used on the reel to maintain the tension of the label tape. Because the labels are closely connected to each other on the label tape, the label tape must be constantly started and stopped.

The label is attached to the case when the labeling wheel moves at the same speed as the case. When the conveyor belt reaches a specific position, the label belt drive wheel will accelerate to match the speed of the conveyor belt, and then decelerate to stop after labeling.

Since the label belt may slip, it has a registration mark on it to ensure that each label is placed correctly. The registration marks are read by a sensor and during the tape deceleration phase the drive wheels are repositioned to correct any position errors on the tape.

Features of labeling machine:

- Use self-adhesive labeling; Automatically count the total daily output and errors;

- Using “Nais” PLC control, “SICK” label dedicated photoelectricity tracking label, reliable and durable;

- Made of aluminum, beautiful and light;

- It can be flexibly designed and customized according to customers;

- Low cost, high efficiency.