Why do you need a mold flipper?

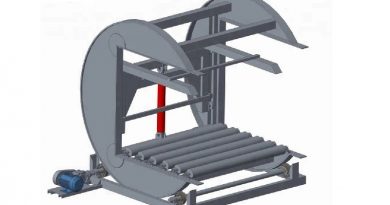

The mold flipper is a turning machine which is relatively unfamiliar to most people, but it plays a very important role in the daily production process. When repairing large and medium-sized molds, turning the mold 0–90° can turn the side that needs repairing to the front of the repairman, so that the repairer can repair, open, close and hoist the mold more conveniently, effortlessly and safely., It is an indispensable auxiliary equipment for stamping workshops, and it is also an ideal equipment for repairing large molds.

The mold turning machine can realize the 90-degree turning operation goal of converting the mold from horizontal to vertical position or vertical to horizontal position. At the same time, it can avoid the use of the original manual method to turn over the heavy molds, which may cause unexpected dangers, resulting in damage to the workpiece; endanger the personal safety of the operator; damage the hoisting equipment. The main feature of this type of equipment is that the product structure is mature and there will be no maintenance accidents.

The mold flipper machine is also a special equipment for the production of the automobile industry. It is used for the overturning of large sheet stacks. It is a necessary auxiliary equipment for the stamping automatic production line. Reduce labor intensity and improve production efficiency.